CLR Industries

Tailor-made products and solutions for air treatment

Systems and technological solutions for regulation, filtration and soundproofing in air transport

Company

Your industrial partner

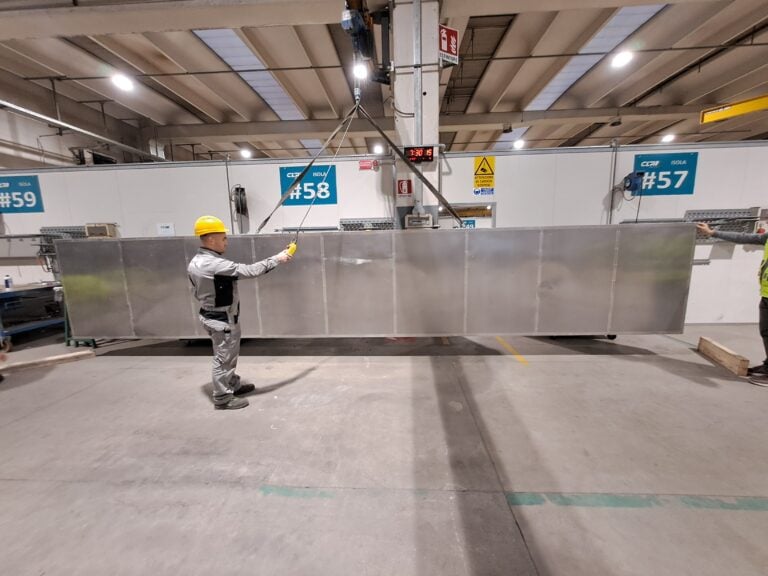

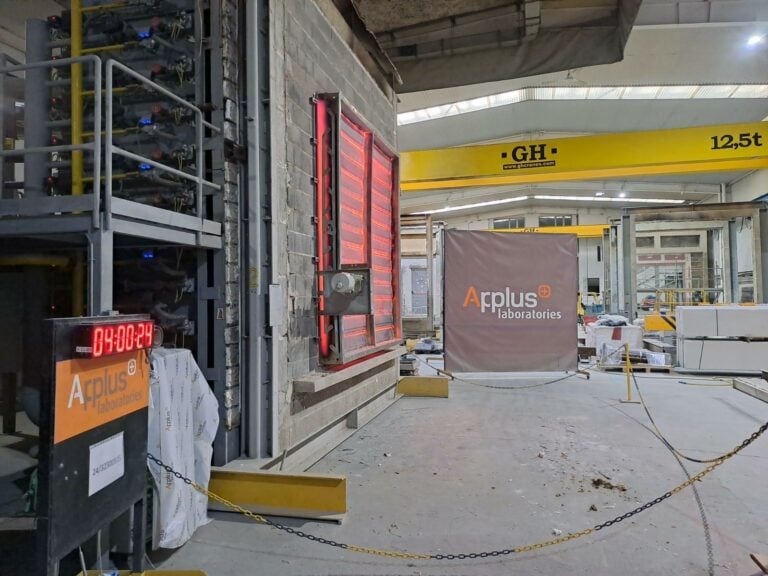

CLR Industries is an industry specialising in the design and manufacture of customised products and solutions for air distribution, control and soundproofing in industrial environments.

We listen to customer needs, conduct in-depth analyses and take care of the acoustic and aeraulic dimensioning of products, with maximum operational flexibility and high levels of quality and performance.

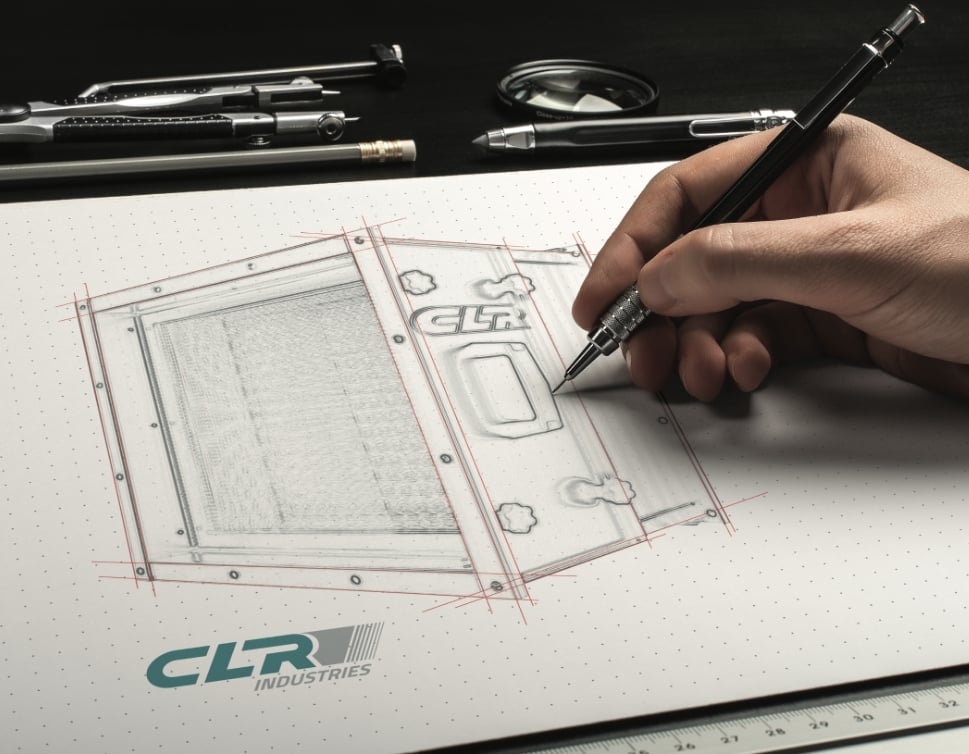

Customised solutions

We produce components for specific requirements

Every industrial air treatment problem requires a tailor-made answer. Thanks to our in-house technical and production structure, we can realise customised projects by conducting preliminary studies, design with 3D modelling software, structural verifications with FEM analysis and fluid-dynamic simulations.

Product portfolio

Our Production

Discover a complete range of standardised models in a variety of configurations and fittings, with a wide dimensional range in multiple materials.